Wir sind Ihr Spezialist für magnetische Felder, magnetische Werkstoffe, Magnetsysteme und magnetische Abschirmungen – von der Beratung bis zur Lieferung von fertigen Bauteilen und Systemen

MFA-110

Mess- und Analysesystem für Magnetfelder mit hoher Auflösung und Speicherung der Rohdaten.

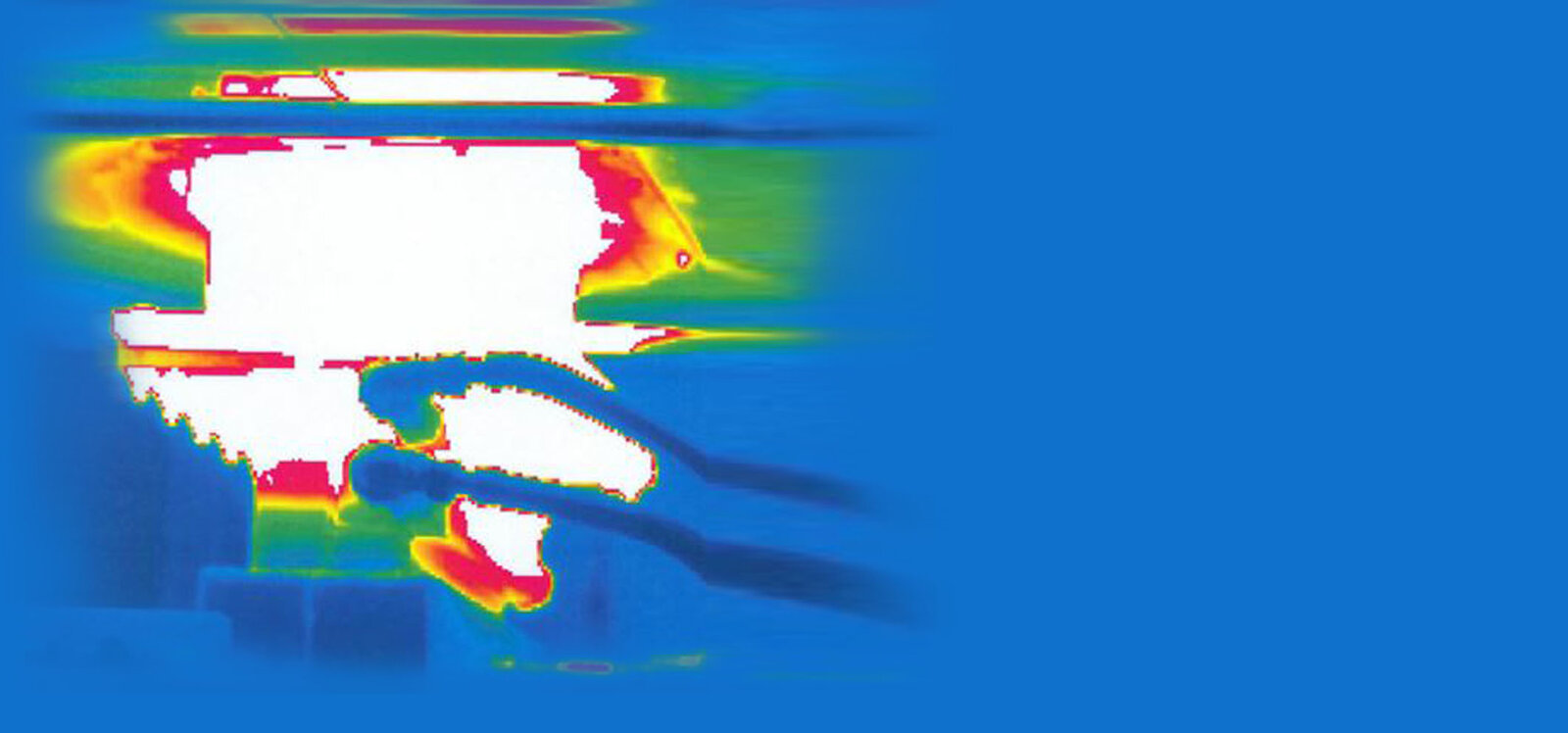

Magnetische Abschirmungen

Berechnung, Entwicklung und Fertigung von Abschirmungen und Abschirmsystemen gegen niederfrequente Magnetfelder.

Magnetische Halbzeuge und Teile

Umfangreiche Lagerhaltung von NiFe- und CoFe-Legierungen in verschiedensten Abmessungen, Konfektionierung, Teilefertigung und Wärmebehandlung.

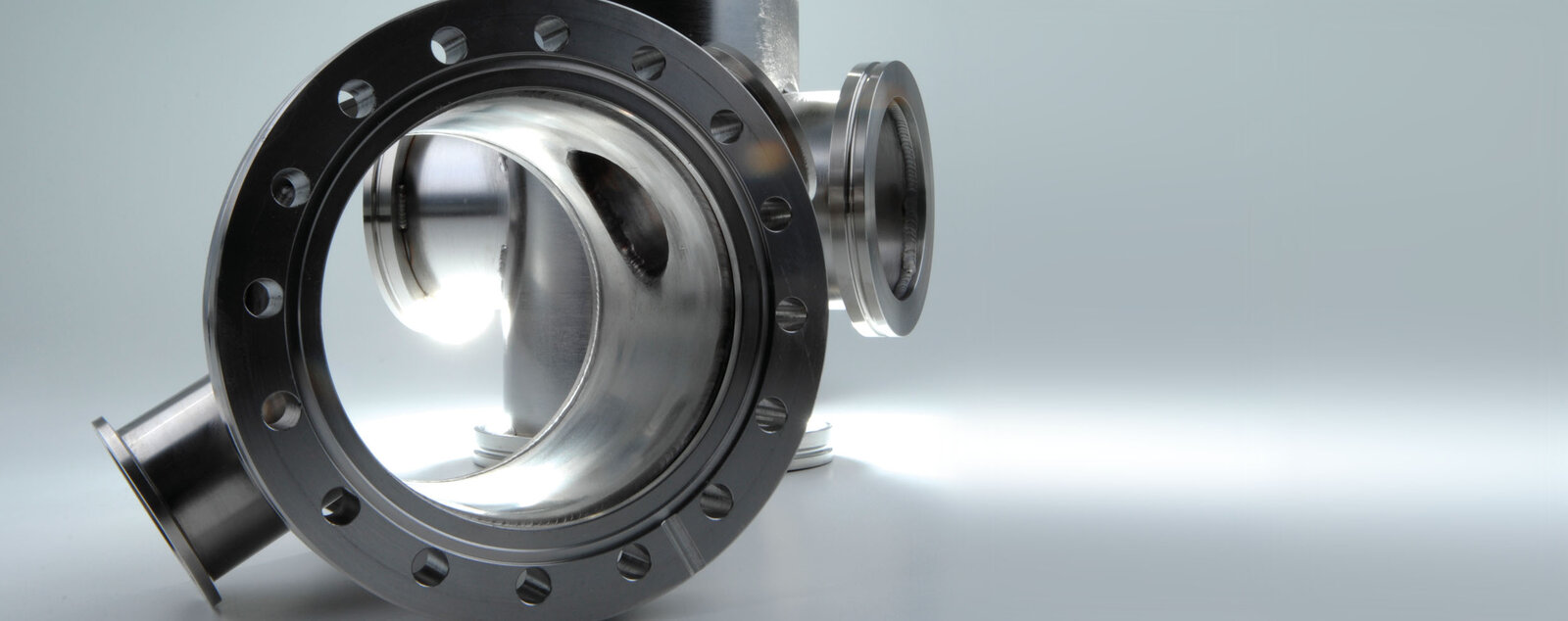

Glühen

Glühen unter Wasserstoff für die magnetische Optimierung oder zum Weichglühen von Edelstählen mit empfindlicher Oberfläche.

Ringbandkerne und Schnittbandkerne

Aus nanokristallinen (VITROPERM®), amorphen (VITROVAC®, METGLAS®) und kristallinen Legierungen. Standard und kundenspezifisch.